Image Source: Google

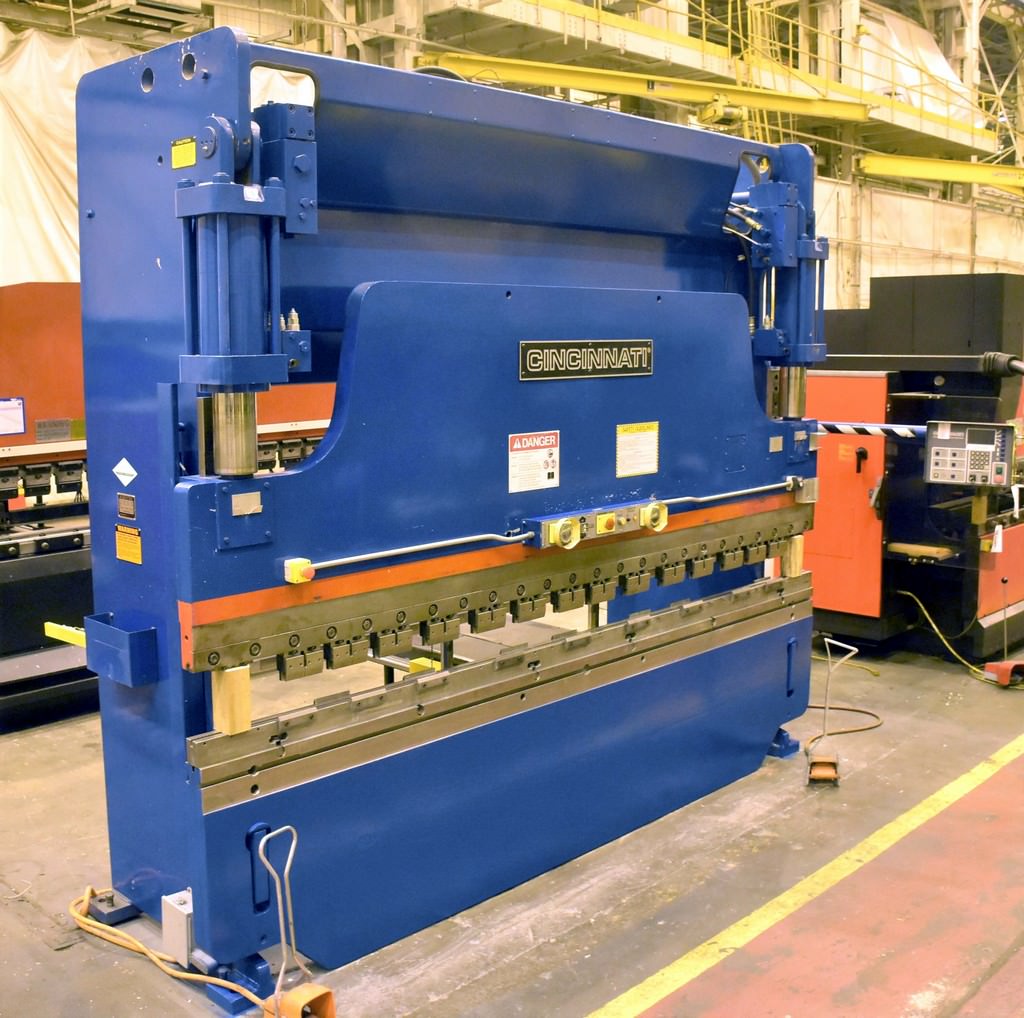

Brake press machines have revolutionized the metal fabrication industry, offering a highly efficient and cost-effective solution for shaping and bending metal sheets. These machines are designed to apply a force to a workpiece, causing it to bend or cut, offering a precise and accurate method of metal forming.

With the advancement in technology and the development of advanced control systems, brake press machines have become even more versatile, and capable of handling a wide range of applications and materials. One of the key factors that contribute to the efficiency of brake press machines is their ability to ensure consistent and accurate bends.

The advanced control systems in these machines allow for precise control of the bending process, ensuring that each bend is made exactly as required. This not only saves time but also eliminates the need for rework, reducing scrap and improving overall productivity. In addition, brake press machines are equipped with features such as back gauges and laser guides, further enhancing accuracy and ensuring consistent results.

Another important aspect that contributes to the efficiency of brake press machines is their versatility. These machines can handle a wide range of materials, including aluminum, stainless steel, and even high-strength materials like titanium. This makes them suitable for a variety of industries, including automotive, aerospace, and construction.

In conclusion, brake press machines have unleashed the potential of metal fabrication, offering a highly efficient and versatile solution for shaping and bending metal sheets. With their advanced control systems, versatility, speed, automation capabilities, and energy efficiency, these machines have revolutionized the industry, enabling manufacturers to produce high-quality products with greater efficiency and cost-effectiveness.